The unit is mainly made of metal, with four large thumbscrews holding the lid in place. I doubt very much that it would cope with being dropped, especially considering how heavy the fitted drive would make it and the fact that the screws fit into plastic mountings. I would like to see some rubber pads on the feet of the unit to both give extra ventilation and improve stability and protect the drive; then again if this causes you worries you could use the included vertical stand.

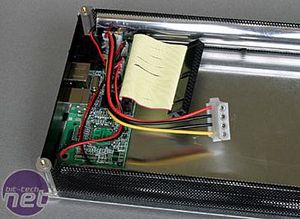

Under the top cover is a printed circuit board with an IDE ribbon and four pin connector for connection to the hard drive.

Also connected to three headers on the PCB are three blue LEDs; These LEDs are in turn connected to acrylic rods that totally span across the front and side panels. As you can see above the acrylic is not entirely clear, with bubbles introduced during manufacturing to spread the light. To ensure no light is wasted the rods are placed in front of a curved metal reflective surface, adding the perfect finish to the lighting effect. If blue isn't your thing replacing the LEDs will be pretty straight forward with a little soldering skill.

This picture shows a close up of the power and activity LED retainers used in the non illuminated version. Using the same parts for all of the enclosure versions reduces production costs, with savings hopefully passed onto distributor, retailer and hopefully you and I. Don't think that you will miss out on activity indication; the whole enclosure flashes as the drive is accessed, read and written to.

Show me lights! I hear you say...

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.